China High-Quality Hollow Fiber Membrane Spinneret Manufacturer Achieves ISO 9001 Certification

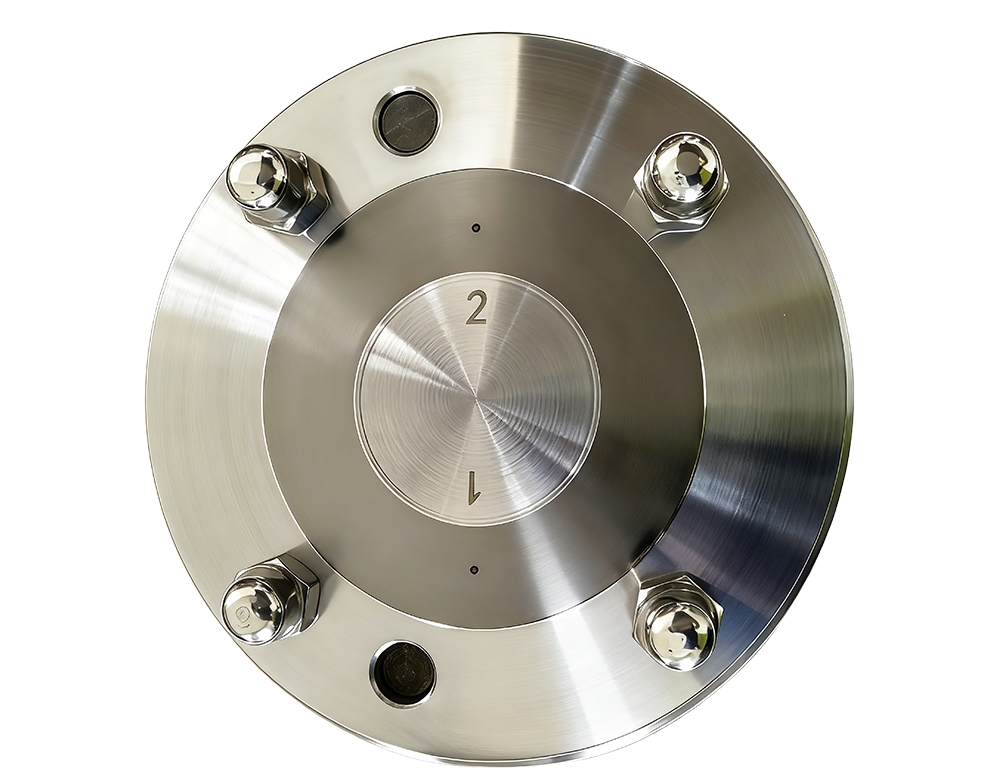

Jiading, Shanghai Jan 4, 2026 (Issuewire.com) - As global markets for high-performance separation materials require increasingly stringent quality assurance standards, Shanghai Trustech Technology Development Co. Ltd has achieved ISO 9001 certification for its manufacturing operations. As an enterprise that specializes in research, development, and production of hollow fiber membrane spinning machines, flat sheet membrane casting machines, precision extrusion tools, and other precision extrusion tools - this organization has earned itself the status of being one of China High-Quality Hollow Fiber Membrane Spinneret Manufacturers. A hollow fiber spinneret is an important piece of equipment, requiring micro-deep hole machining technology for consistent dope extrusion. Trustech was awarded this certification as formal validation of their ability to maintain structural concentricity within an accuracy range of 0.003mm, an essential technical requirement for producing membranes used for hemodialysis, wastewater treatment and gas separation applications. By standardizing complex fabrication workflows Trustech ensures every component delivered to international manufacturers meets exact mechanical specifications for safe long-term industrial operation.

Global Market Trajectories and the Need for Standardization

The Structural Transition toward High-Consistency Industrial Fabrication

The international membrane technology sector is currently witnessing a monumental transition towards automated production environments that produce at high volumes. As both municipalities and industries prioritize resource recovery and environmental safety, hollow fiber membranes have become increasingly sought-after across water treatment, biotechnology and pharmaceutical sectors. Market data indicates a shift to continuous manufacturing processes as an increasingly attractive alternative to batch-based methods of production. This development has necessitated high-precision components that can maintain mechanical stability and structural uniformity across 24-hour industrial production cycles. Meeting international quality standards has become essential to equipping global infrastructure projects.

Technological Considerations in Specialized Pharmaceutical and Medical Separation

With such critical applications as biopharmaceutical purification and artificial lungs (ECMO), any error in membrane morphology is irreparable. Industry has recently adopted zero-defect manufacturing philosophies that call for extreme mechanical precision and real-time monitoring of production lines. As global manufacturing shifts towards high-value technological innovation, emphasis has shifted toward localizing production capabilities that ensure uniform pore distribution among millions of fibers. Modern industrial systems must prioritize components that can handle various polymer chemistries - PVDF, PES and PAN - while meeting the stringent safety and purity standards set by global healthcare and beverage industries.

Verification and Risk Mitigation within ISO 9001 Certification

Receiving ISO 9001 certification demonstrates a manufacturer has implemented an efficient Quality Management System (QMS) which exceeds international benchmarks in terms of consistency and reliability. Manufacturers that specialize in precision extrusion tools require certification through a rigorous audit that covers every stage of production - from raw material metallurgical analysis to final component testing. Verification ensures that an organization maintains documented procedures for identifying and mitigating technical risks during the machining process. This approach ensures every spinneret produced meets specified mechanical tolerances to prevent fiber eccentricity or structural failures in final membrane products.

More On Toptelecast ::

- SAINTY at ISPO Munich: Showcasing Excellence as A China Leading Men's Women's Puffer Jacket Manufacturer

- Austin Morgan, Recognized by BestAgents.us as a 2025 Top Agent

- Injured in Houston? The Law Office of Udo Ezeamama Delivers Aggressive Representation for Personal Injury Victims

- US Businesses Shift to Remote Full-Stack Developers as Tech Talent Shortages Rise

- Can You Make Money Without a Traditional Job? Printify Leads the Shift to Flexible, Low-Risk Online Earning

Standardizing Micro-Machining and Inspection Protocols Within ISO 9001, manufacturing high-quality spinnerets requires standard micro-deep hole processing methods. Certification ensures that automated machining centers and special fixtures are calibrated at regular intervals to maintain clamping accuracy of 0.002mm, as well as standardized inspection protocols for hole concentricity and surface roughness. Trustech adheres to internationally recognized quality controls that guarantee L/D ratios and internal geometries remain constant across production batches, giving industrial clients confidence for multi-line capacity expansions.

ISO 9001 Certification Is Committed to Continuous Process Improvement and Compliance For international partners, ISO 9001 certification signifies an ongoing cycle of refinement and technical evolution, through feedback loops and corrective action protocols that promote manufacturing efficiency. Specifically for membrane manufacturers, this means incorporating fluid simulation and structural analysis advancements into production workflow using standard change management procedures - something membrane manufacturers cannot do on their own without this commitment to continuous process improvement and compliance. Providing Reliable Collaboration Platform

Core Technical Competencies and Application Scenarios

Trustechs competitive advantage lies in its ability to integrate precision mechanical engineering with advanced polymer science research, enabling the delivery of high-quality, cost-effective membrane manufacturing solutions. As a pioneer in hollow fiber membrane spinning machines and spinneret technology, Trustech introduced the FCT (Fast Change Technology) spinneret with its 5th-generation platform and has since advanced 6th through 9th generation technologies. Serving as Editor-in-Chief of the Hollow Spinneret standard (T/SHDSGY058-2022), and with equipment covering NIPS (MSCS), TIPS, PTFE, and flat-sheet casting processes, Trustech has accumulated over 40 authorized patents as a National High-Tech Enterprise and was the first professional organization in China to conduct multi-hole spinneret structural analysis and fluid simulation. These capabilities optimize flow rate and pressure distribution to meet the phase-separation requirements of diverse polymer systems, ensuring certified quality management across even the most advanced designs. The FCT spinneret offers broad dope-viscosity adaptability, high spinning stability, modular and integrated construction, robust needle design, easy cleaning and maintenance, high reliability, extended service life, and simplified servicing for MBR braided tube coating applications. Trustech's certified systems are widely applied in life-critical medical fields such as hemodialysis and ECMO, as well as in environmental purification including MBR and industrial effluent treatment, with proven reliability across 39 countries worldwide, an AAA credit rating, and active membership in the Membrane Industry Association of China (MIAC).

Trustech provides Research and Industrial Scalability Support Trustech maintains strong Enterprise-Academics-Research cooperation bases with top institutions, such as Changchun Industry University. By offering lab equipment that accurately simulates industrial-scale production parameters, Trustech acts as an intermediary between material innovation and commercial reality. With more than 630 customers served and ISO certified processes that ensure technical infrastructure remains robust and scalable; Trustech stands as a proven strategic partner.

Conclusion: Establishing the Standard for Precision Manufacturing

Trustech has earned ISO 9001 certification todemonstrate dedication to providing customers with mechanical integrity and transparency within the membrane industry. The companys advanced precision engineering is combined with standard quality management, effectively meeting modern production challenges such as consistency and scalability - this makes Trustech an integral contributor in global health, clean water provision, and industrial efficiency infrastructure development.

Focused on quality consistency and innovative machine design, the organization continues to equip global membrane industry players with tools necessary for solving complex separation challenges. Adhering to international manufacturing excellence practices, they support the continued evolution of separation technology while helping manufacturers produce high-performance membranes with sustainable future in mind.

For further details regarding technical specifications, product portfolios and corporate developments please visit: https://www.xtrustech.com/

Media Contact

Shanghai Trustech Technology Development Co., Ltd.

Source :Shanghai Trustech Technology Development Co., Ltd.

This article was originally published by IssueWire. Read the original article here.