Urgent to Get Custom Metal Fabrication Service? Openex is the Top Choice

Xiamen, Fujian Dec 15, 2025 (Issuewire.com) - Companies are always looking for partners that can provide more than a simple product in today's fast-paced world of manufacturing. A true partner, a provider of full services who can manage the complexity of a project is what they need. The stakes increase when the project includes large-scale custom metal components. The challenge of managing multiple vendors and ensuring quality while meeting deadlines is overwhelming. The concept of "one-stop shopping" is invaluable in this situation. Openex is the best choice for any business looking for a reliable Custom Metal Fabrication Service. Its foundation is built on massive scale, comprehensive service, and a commitment to quality.

Openex Advantages: Unmatched Capabilities & Integrated Service

It's not just about the lowest price anymore when choosing a fabrication partner. The best solution is one that offers a seamless, complete package while minimizing risk and maximizing efficiency. Openex's entire business model is based on this principle. The company's one-stop shop provides a complete range of services, eliminating the potential for quality problems and logistical issues that can arise when projects are fragmented among multiple suppliers. The integrated approach makes sure that all steps, from the sourcing of raw materials to the final finishing are managed by a single quality control system.

Openex's core advantage is its advanced and extensive capabilities. Openex can flexibly use more than 1,000 sets advanced CNC machines for metal fabrication. This gives them the ability to handle industrial parts with large range of sizes, including sheet metal fabrication with thickness under 3mm, or large fabrication with thickness over 50mm. It's not just about their size, but also about the precision and flexibility of their technology.

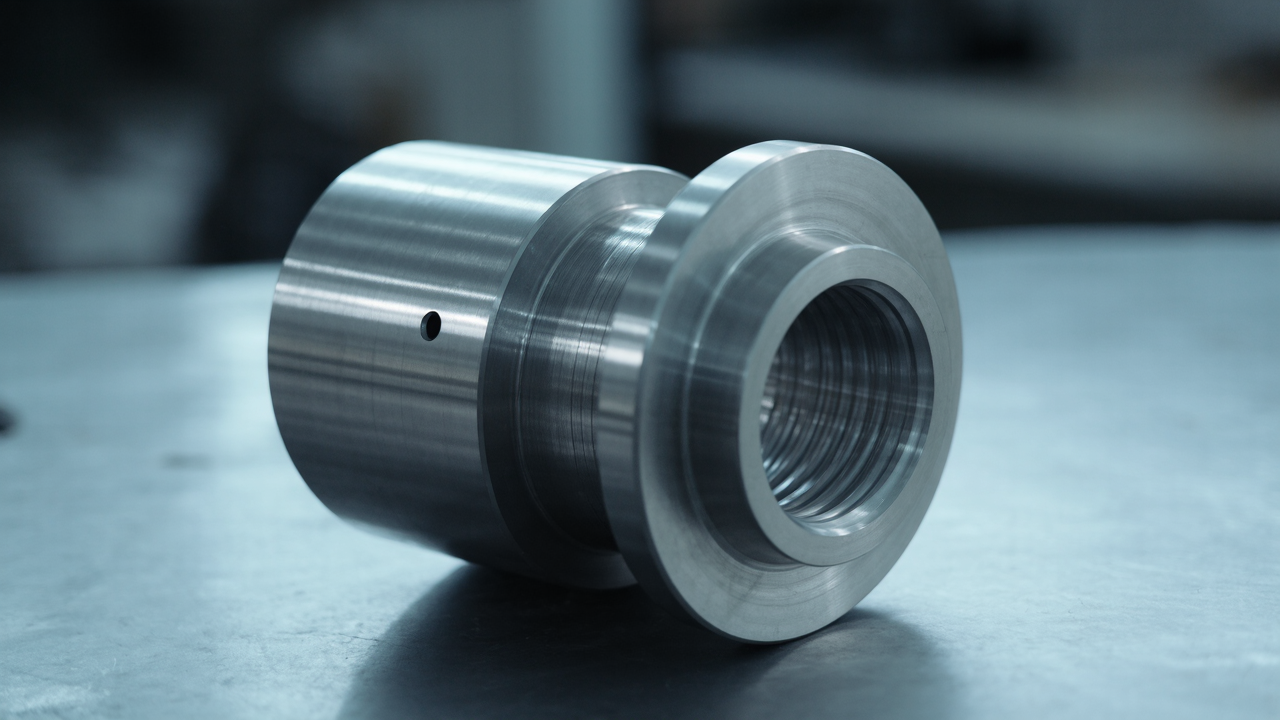

Precision Machined Parts: Openex is able to produce large custom machined parts that are extremely accurate. This is crucial for components with tight tolerances or complex geometries. It ensures they will fit seamlessly into larger assemblies.

Diverse Cutting Technology: A wide range of cutting machines are available in the company's cutting department, including laser, water jet, plasma, robotic contour-beveling, flame and sawing. The company's versatility allows it to work with an array of materials, thicknesses and technologies.

Expert Welding: Openexs cutting-edge welding equipment and highly-skilled personnel are essential for producing strong, durable and reliable fabrications. They are experts in multiple welding techniques, which ensures the highest possible quality of welds. This is a must for heavy-duty industrial applications.

Massive Scale Forming: Only a few companies are able to match Openex in terms of their capacity for large parts. The company's enhanced plate rolling division can roll plates up to 5 000mm wide and 200mm thick. Their press braking capability can form parts as thick as 100mm. This capability is crucial for the manufacture of large-scale equipment and structures.

More On Toptelecast ::

- Diane Tinsley, Recognized by BestAgents.us as a 2025 Top Agent

- Sourcing from a China Best Seamless Steel Pipe Manufacturer: Is It the Right Choice?

- Hansen Surfboards Encinitas San diego CA Jackets shirt denim Collection Mens Apparel Footwear Modern Coastal Lifestyle

- LoopNote Meet Launches as a Lightweight Fireflies.ai Alternative for VCs, Founders, and Remote Teams

- DL Mining launches simple cloud mining service, bringing passive income, Bitcoin price rises

Quality Assurance and Comprehensive Finishing: Openex provides services such as painting and rigorous tests. Openex's strict quality assurance procedure ensures only conforming components are delivered to their customers. This provides a final level of confidence in every component.

Openex's combination of comprehensive services with massive scale capabilities makes it a leader capable of taking on large-scale projects that other companies cannot.

Case studies and applications of reliable metal fabrication services

It is not the equipment list that defines a company's true worth, but rather its ability to use those capabilities in solving real-world issues. Openex's metal fabrication services is trusted by clients in a wide range of industries where performance and quality are important.

Heavy Construction & Mining

Components in the heavy equipment industry must be able to withstand extreme stress and perform reliably even in harsh environments. Openex is the go-to supplier for large machinery's fundamental structures.

Case Study of a Client: Excavator Frames An international manufacturer of excavators was looking for a partner who could fabricate and machine an oversized series of frames. To ensure that the frames were able to handle the heavy loads of an operating machine, the project required exceptional dimensional accuracy as well as a high degree of welding integrity. Openex's single-source model enabled them to manage all aspects of the project, from cutting the steel plates and forming them to welding the structure and precision machining after fabrication and welding. This seamless integration produced a product which met all specifications before schedule, proving that a single source supplier is worth its weight in gold.

Oil & Gas and Energy Sector

Energy industry components must be able to withstand extreme temperatures, pressures and corrosion.

Client Case Study: Wind Turbine Nacelles An energy company needed a large number of fabricated nacelle base for its new line of turbines. These structures house the core components of the wind turbine and had to be strong, aligned perfectly, and built to last for decades. Openex's experience in large-scale rolling and welding of plates was essential. Openex delivered a product which not only met all the engineering drawings of the client but also passed non-destructive tests, ensuring integrity and safety in the final installation.

Marine and Shipbuilding

Marine industry requires large, complex and corrosion-resistant parts. These projects are massive in scale, and each part must adhere to strict maritime standards.

Case Study of a Client: Ship Hulls An important shipyard was looking for a partner who could fabricate large hull sections to be used on a new vessel. These components required complex cutting, welding and forming with strict quality controls to ensure structural integrity and watertight seals. Openex's capacity to manage large-scale projects, and their unwavering dedication to quality, allowed them to deliver sections on time to the exacting standards needed for a seagoing vessel.

The most important decision that a business can make in the modern world of manufacturing is to choose the right partner. The future of Metal Fabrication does not only revolve around technology, but also about reliability, integration, and commitment to quality. Openex's position as a leading provider of large-scale custom fabrications has been cemented by its comprehensive one-stop-shop solution.

Selecting a fabrication partner in today's complex manufacturing environment is a crucial decision. Finding a reliable partner who can provide a seamless, complete solution is more important than finding a supplier.

Openexwww.cncmetalworking.com is ready to be your partner with their integrated one-stop shop model, large-scale capabilities and unwavering dedication to quality.

Media Contact

Openex

+86 186 5928 0806

No. 99 Yilan Rd., Xiamen , CN.

Source :Openex

This article was originally published by IssueWire. Read the original article here.